What are the Advantages of a Portable Stretch Wrapper Robot?

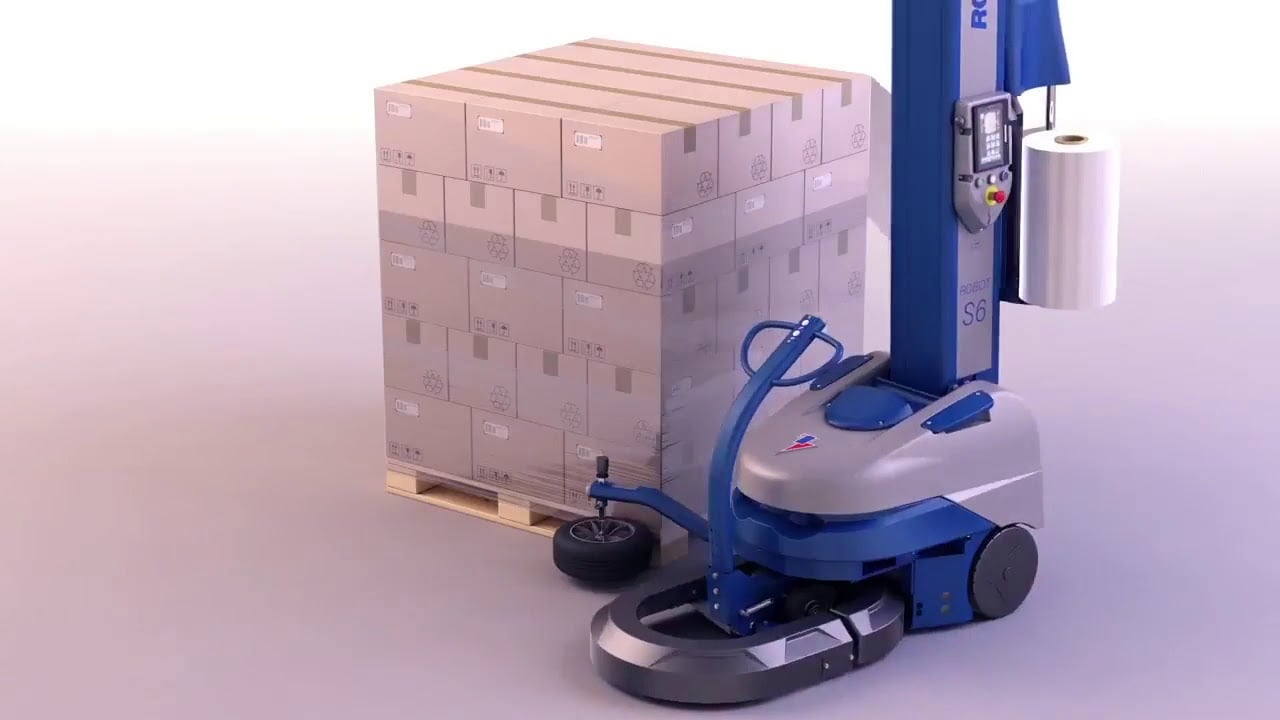

We offer a wide-range of stretch wrapping systems but the Robot S6 turns the most heads. This semi-autonomous stretch wrapper is a portable stretch wrapping robot on wheels. Some people may instantly see the unique solutions this stretch system offers and others are just intrigued by the wonders of this whirling little pallet wrapper. In this article, we discuss the benefits of this portable pallet wrapper and help evaluate whether the Robot S6 Stretch Wrapper is right for you.

Gather a Better Understanding of the Setup of Your Operation

For operations to understand which machines can do the most for them, they must first develop an understanding of their own setup. Large facilities are often hurting for space, making the addition of a large piece of equipment cumbersome and unrealistic. If your facility can’t handle another gigantic machine or doesn’t have space to create a dedicated area to stretch wrapping, then the Robot S6 Stretch Wrapper might be the right option for you.

This machine is best for operations that wrap loads in multiple places throughout their facilities. The Robot S6 is a portable stretch wrapper. This means it can move to where it is needed quickly and easily. It provides the flexibility of bringing the stretch wrapper where it’s necessary at any time. If you have dramatic shifts in product or seasonality, this system can provide you with flexibility needed. This is also a great consideration for rework or hand-stacked pallets.

This wonderful convenience can improve productivity by up to 25 percent. Any productivity increase is huge to warehouse operations, and the outstanding portability of this machine is a simple way to increase productivity and efficiency. The machine is also battery-powered, so it does not require a plug or outlet. Plugs are what keep traditional stretch wrappers stationary. Instead, simply recharge the battery for the Robot S6 Stretch Wrapper every night to allow for maximum efficiency. Nightly recharging works to prevent mid-day charging, which can cause unplanned downtime.

Examine Your Typical Pallet Loads for More Information

Another crucial thing to examine in your business operation is your typical pallet loads. The size and shape of your pallet loads determine which machines will and will not work with your operation. Take note of what your pallet loads look like so you can accurately describe them to a professional who can address your secondary packaging needs and offer prompt and accurate recommendations for your operation.

If you regularly wrap heavy, long, or wide pallet loads, then your operation may benefit from a stretch wrapping machine that stays on the floor. Machines such as a spinning turntable stretch wrapper have weight limits and size limits because it requires a worker to lift the pallet off the floor. When using a Robot S6 Stretch Wrapper, you don’t have to worry about this. You can wrap any weight pallet or any shape without worry. The machine allows the pallet loads to remain on the floor.

Discover the Added Stability It Brings

One common problem some facilities run into often is a lack of stability in their pallet loads. The Robot S6 Stretch Wrapper can wrap any standard pallet load. It is also able to help with heavier and more irregular loads as it can wrap any length or weight pallet load.

Our machines at Robopac USA employ superior technology to ensure each pallet load is wrapped with the exact right amount of containment force every single time. Containment force is the key to safe and stable shipment loads. Our exclusive Cube Technology allows for multi-level variable pre-stretch, which ensures the highest level of containment force and the best film economy for every load. You can even use any stretch film without worry. By delivering the optimal containment force at each level of the load through the allowance of up to nine adjustments each load, you can get more stable loads with less headache. The right amount of stretch film goes exactly where it has the most impact on a load’s stability.

Explore the Other Wonderful Benefits of a Robot S6 Stretch Wrapper

The Robot S6 Stretch Wrapper has all the above benefits and more. Below are just some of the countless advantages that your facility can enjoy if you invest in one of these machines.

Improved Ease of Use

The Robot S6 Stretch Wrapper is easy to use. This is a vast improvement from more complicated and hard-to-use stretch wrapping machines. It is also a huge improvement from hand wrapping pallets as that tasks require heavy lifting, lots of strength, and it isn’t very consistent. This machine has an easy-to-use, intuitive, seven-inch touchscreen. It’s so easy that anyone can do it!

Drastic Reduction of Film Usage

The machine also significantly reduces the use of stretch film, thanks to Cube Technology, exclusively offered on Robopac USA machines. Cube Technology reduces film usage by between 30 and 55 percent. This improves your operation’s sustainability and cuts down on film waste. Less film usage and less film waste mean that you spend less money on film. You save money and time with one handy machine.

Added Convenience

The Robopac Robot S6 Stretch Wrapper adds so much convenience to an operation that you’ll wonder how you did things before investing in one. These machines pay for themselves through additional productivity, decreased spend of film, increased sustainability, and more stable loads. More stable loads reduce product damage!

If any of these benefits sound like they may improve your secondary packaging operation, then this might be the perfect machine for you.

This article was originally published by RobopacUSA.